WELCOME to our TECHNICAL QUIZZES

WELDING AND MATERIALS PROPERTIES QUIZ

Each of our technical quizzes is compiled to give you an insight into the technical coverage of codes and standards included in various certification exams in the integrity industry. We’ve also included areas of specific technical interest on other integrity topics.

There are only 5 questions per quiz. Have a go at them first then check the answers and see how you’ve done. There’s a ‘5-minute coaching section’ at the end of each quiz set to guide you on the relevant technical subject.

Material properties

Knowledge of the mechanical properties of materials is often seen as something that should be left to metallurgists and welding engineers. In reality it is a central topic to many aspects of plant integrity including design, code compliance, inspection, repairs, FFP evaluation, testing and certification. The ability to understand the contents of a manufacturer’s material certificate is vital for anyone working in the field of mechanical integrity. It is not often well covered in further education courses, leaving many people with gaps in this vital knowledge area

Try these five quiz questions about the mechanical properties of pressure equipment material and see how you do.

Q1: Material properties

Which of these is not a commonly defined mechanical property of metals used for fabricated pressure equipment?

a) Impact strength

b) Ductility

c) Hardness

d) Malleability

Q2: Mechanical properties

Which of these is not a mechanical property of stainless steel?

a) Yield strength under a tensile load

b) % Chromium content to reduce corrosion

c) % Elongation during a tensile test

d) Charpy or Izod impact strength

Q3: Material tensile tests

Which mechanical property of a metal is quantified by the terms (% E) and (% A) on its material test certificate?

a) Strength

b) Ductility

c) Elasticity

d) All of the above

Q4: Effect of Carbon content on the properties of steel

On balance, medium carbon (0.4% C) steel can be expected to be fairly;

a) Soft

b) Ductile

c) Strong

d) Weldable without PWHT

Q5: Material for welded joints

A fillet welded joint on the saddle of a pressure vessel will be subjected to mechanical vibration when in use. The most suitable steel to make it from will be one that has;

a) Tensile strength of 35ksi

b) Yield strength of 350MPa

c) Hardness of 350HB before welding

d) >2% C content

Once you have had a try at the questions, have a review of The Answers

If you didn’t get them all correct, have a look through our 5-minute coaching points below

5-MINUTE COACHING

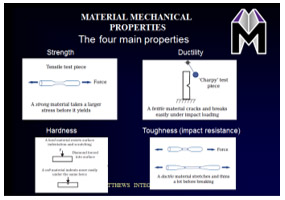

Material mechanical properties

One excellent document covering the properties of steels relevant to the integrity industry is API RP577 Welding and Metallurgy. It forms part of the body of knowledge of most of the API Inspector Certificates. As an integrity inspector/engineer the main mechanical properties you need to know about are yield/tensile strength, ductility (%E, %A), Charpy impact strength and hardness, how they are related, and how they are affected by the %Carbon in the steel.

See our short slide presentation covering this topic