WELCOME to our TECHNICAL QUIZZES

Each of our technical quizzes is compiled to give you an insight into the technical coverage of codes and standards included in various certification exams in the integrity industry. We’ve also included areas of specific technical interest on other integrity topics.

There are only 5 questions per quiz. Have a go at them first then check the answers and see how you’ve done. There’s a ‘5-minute coaching section’ at the end of each quiz set to guide you on the relevant technical subject.

FFP EVALUATION QUIZ

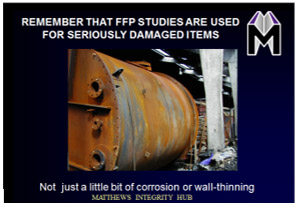

FFP evaluations are technical assessments carried out on pressure equipment or structural items that are affected by corrosion or other damage mechanisms to the extent that they no longer comply with the defect acceptance criteria laid down in either the construction code or the relevant post-construction code. FFP evaluations are therefore out-of-code assessments. There is always some risk involved when continuing to operate a corroded item under the guise of a FFP assessment.

The most common FFP assessment document is API Recommended Practice (RP) 579 Fitness-for-service. This consists of more than 1000 pages of technical analysis methods covering many of the different damage mechanisms(DMs) described in API 571 Damage Mechanisms affecting fixed equipment in refineries.

API RP 579 FFP assessments are not straightforward. There may be several different ways to assess a damaged item, that will give different answers. There are also limitations to the validity of FFP assessments, depending on the nature and location of the DMs and the operating conditions of the equipment being assessed.

Try these five quiz questions about the basics of FFP assessments and see how you do.

Qu 1 FFP Principles

API RP 579 assessments cannot give very accurate results when which one of the following is present in the component being assessed?

a) Welds

b) Dynamic stresses

c) Principal stresses

d) Stresses above the material’s yield point

Qu 2: Vessel stresses

Where is the highest stress located in a vessel hemispherical head under internal pressure?

a) In the hoop plane

b) In the circumferential plane

c) In the knuckle area

d) None of the above

Qu 3: Flange stresses

Two mating raised face (RF) flanges have been over-machined to remove corrosion and their flange thickness dimensions are now outside code (ASME B16.5). They are now joined and the bolts over-tightened. What kind of stress predominates in the flanges and could lead to leakage or flange failure?

a) Torsional stresses >90% yield

b) Compressive

c) Bending

d) Buckling

Qu 4: Vessel FFP assessment

FFP assessments on corroded pressure vessels with nozzles can be very inaccurate when the vessel has not required PWHT and the corroded area for assessment is located?

a) Inside a nozzle’s limit of reinforcement

b) On a shell circumferential (SAW) weld

c) Outside a nozzle’s limit of reinforcement

d) Within 5 x material thickness of a shell longitudinal weld (GTAW [TIG] root with SMAW fill)

Qu 5: Stress in pipework

A simply supported thin walled pipe is loaded uniformally along its length and contains an internal pressure. Which of these statements is untrue?

a) Stress in the pipe is assumed to be 2-dimensional

b) Tensile stress increases with increasing distance from the neutral axis

c) Bending stress is always larger than the pressure stres

d) The second moment of area ‘inertia’ I is constant along the length of the pipe

Once you have had a try at the questions, have a review of The Answers

If you didn’t get them all correct, have a look through our 5-minute coaching points below

5-MINUTE COACHING

THE PRINCIPLE OF API 579 FFP STUDIES

Fitness-for-purpose (FFP) assessments (termed fitness-for-service (FFS) assessments in the USA) play a prominent role in the world of in-service inspection. Their most common use is for pressurised equipment and structural components where integrity is an important issue.

FFP ASSESSMENTS ¾ WHAT ARE THEY?

A FFP assessment is a set of calculations performed on a component that contains some kind of feature that is suspected to affect its integrity. It is pure calculation so, although the calculation routines are based on engineering reality (supposedly), it is a purely theoretical exercise rather than a practical one. The whole concept of FFP assessment carries with it a specific set of terminology, which, whilst perfectly consistent in itself, does not necessarily coincide with common, or even general engineering usage, of the words ¾ so it can be a bit confusing

FFP ASSESSMENTS ¾ THE APPROACH

The central concept of a FFP assessment is that it looks at the effect on FFP of an existing flaw. It tries to predict how and when the flaw will cause the component to fail ¾ and it does this by considering the various failure mechanisms (ways of failure) that could happen. There is a graded approach to assessment with three possible levels of investigation. The higher the level of investigation, the more the failure mechanisms are considered in depth, and the greater the mathematical rigour that is used.

FFP approach ¾ two key points

A key point of the approach of a FFP assessment is its relationship to code compliance e.g. the compliance of a pressure vessel with the construction requirements of ASME VIII, EN 13445 or another of the recognised published technical standards. Note two key points:

- Most FFP assessments are done on components that are outside code compliance limits in some way i.e. they are rejectable under the code. This means that FFP assessments are, fundamentally, based on different acceptance criteria than design codes. This introduces the apparent paradox of there being more than one valid set of flaw acceptance criteria for the same engineering component.

- The defect acceptance criteria given in technical codes (ASME VIII, EN 13445 etc) are not indicators of FFP. They are best thought of indicative levels that can be reached if all the code requirements on materials, QA/QC, design features etc. are met

The inference here is that the existence of out-of-code flaws (using the FFP assessment term) does not mean that a component is not fit for purpose or unsafe. It means, merely that it does not meet the full requirements of the code, some of which may be FFP-related but many of which are chosen for practical reason, or simply convenience. All of this reinforces the need for in-service inspectors to appreciate the basic principles of FFP assessment and recognise the different approach to that of simple code compliance.

See our short slide presentation covering this topic