WELCOME to our TECHNICAL QUIZZES

DAMAGE MECHANISMS (LOWT) QUIZ

Each of our technical quizzes is compiled to give you an insight into the technical coverage of codes and standards included in various certification exams in the integrity industry. We’ve also included areas of specific technical interest on other integrity topics.

There are only 5 questions per quiz. Have a go at them first then check the answers and see how you’ve done. There’s a ‘5-minute coaching section’ at the end of each quiz set to guide you on the relevant technical subject.

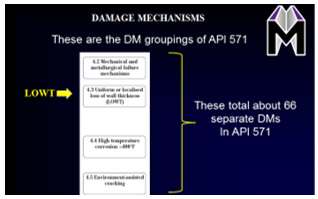

Damage Mechanisms of API 571

API 571 is one of the most useful of the API codes. Although it is aimed mainly at refineries, it is also in use across many different process industries, where it is accepted as a base reference document about damage mechanisms. It splits DMs into five categories:

- Mechanical and metallurgical failure mechanisms

- Uniform or localised loss of wall thickness (LOWT)

- High temperature corrosion (>400oF)

- Environment assisted cracking

- LOWT mechanisms specific to refineries (mainly caused by acids)

The most common category is normally that of loss of wall thickness (LOWT) corrosion of various types. Note the predominance of acidic corrosion in the last category above. Process chemicals containing acid compounds are used in many applications in the oil refining process and like to corrode ferrous metals with which they come into contact. They therefore add to the overall inventory of LOWT DMs found in process plant.

Try these five quiz question related to LOWT Damage Mechanisms and see how you do. They are not so easy. See the 5-minute coaching module after the quiz if you want to learn more.

Qu1. Atmospheric LOWT corrosion

A lot of LOWT on operating plant is caused by straightforward atmospheric corrosion. For low carbon steel which is externally coated, LOWT caused by atmospheric corrosion is likely to be;

a) Localised or general

b) Around welds

c) General

d) Localised

Qu2. Elevated temperature LOWT corrosion.

For unlagged vessels or pipework operating above 175 degC, atmospheric corrosion;

a) Is unlikely

b) Increases as temperature increases

c) Decreases as temperature decreases

d) Stays at a constant rate

Qu3. Dissimilar weld corrosion.

Dissimilar welds can be susceptible to LOWT corrosion. The most vulnerable region in a dissimilar metal weld is;

a) Almost anywhere on or near the weld

b) Melted areas

c) The weld root

d) The area influenced by heat input but not melted

Qu4. Acidic LOWT corrosion

Acids play a large part in LOWT corrosion found in refineries. Which of these refinery-specific LOWT DMs is not the result of acidic corrosion?

a) Amine corrosion

b) Hydrogen Sulphide (H2S) corrosion

c) Ammonium bisulphide corrosion

d) Phenol corrosion

Qu5. Acidic LOWT corrosion

Some chemicals found in refineries have serious LOWT corrosion effects on low plain carbon steels. Which of these LOWT acidic DM causes corrosion not by the chemical itself, but by gases dissolved in it?

a) Amine corrosion

b) Ammonium chloride corrosion

c) Napthenic acid corrosion

d) Hydrofluoric acid corrosion

Once you have had a try at the questions, have a review of The Answers

If you didn’t get them all correct, have a look through our 5-minute coaching points below

5-MINUTE COACHING

LOWT DAMAGE MECHANISMS

See our short slide presentation covering this topic