THE SOURCE (SHOP) INSPECTOR ROLE

THE CURRENT TREND is for inspectors who perform their inspections in manufacturing works to be called Source Inspectors, rather than the old term of ‘shop inspector’ or ‘quality inspector’. Unusually for the inspection world, this is also an area where developments are happening quickly in the structure of personnel qualifications and certification that support the business. This is sufficiently widespread to be a distinct trend rather than a quick fashion so you need to keep on top of it. Typical job titles in this new world ofsource inspection include:

- Source inspector

- Shop inspector

- Authorised inspector (ASME)

- Welding inspector

- Factory acceptance inspector

- Resident inspector

- Quality inspector

The job

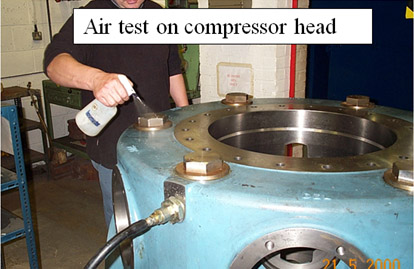

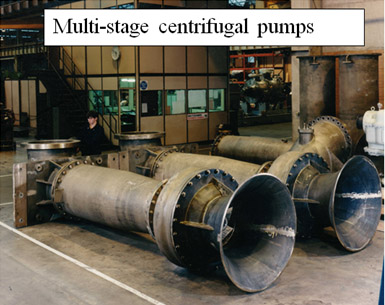

The Source Inspector job involves INSPECTING NEW EQUIPMENT under construction in the manufacturers work. The activity is witnessing rather than personally doing material tests, weld tests, fabrication assembly NDT, pressure testing and visual/dimensional checks against drawings and specifications. Source inspectors work largely alone, reporting to an office-based inspection co-ordinator.

Skill levels and certification

Source inspectors gain most of their skills by experience acquired during previous jobs in plant operations, mechanical fitting, NDT, QA/QC or similar. A common route is to start with achieving certification as a weld inspector (PCN/CSWIP/CWI etc.) supplemented by NDT certificates. As a new trend there is a structure of source inspection certificates initiated in USA (API SIFE/SIRE), widely adopted by many other countries because they don’t have their own.

ACRONYM SOUP

PCN: Personnel certification for non-destructive testing (UK)

CSWIP: Certification scheme for welding and inspection personnel (UK)

CWI: Certified weld inspector (USA)

API: American petroleum institute

SIFE: Source inspector (fixed equipment)

SIRE: Source inspector (rotating equipment)

SIEE: Source inspector (electrical equipment)

Practical-v-academic ability?

For static (fixed) equipment such as structures, pressure equipment, cranes etc., source inspection requires practical skills in interpreting codes specification and purchaser requirements. The ability to read engineering drawings and PIDs is essential, plus observation skills and an appreciation of how manufacturing processes are done.

Witnessing performance tests on rotating equipment (pumps, compressors, turbines etc.) is a much higher-level activity, for this you need some knowledge of fluid, mechanics, machinery performance and vibration – all involving a level of college mathematics. Many source inspectors don’t feel comfortable with this and so stay with pressure equipment and structures.

Are source inspection skills transferrable?

Skills are easily transferrable between employers but not easily between disciplines. Static, rotating and electrical equipment inspections are very different subjects and its best to stick to your own discipline. Most source inspectors stay in the same role, gaining increasing experience rather than progressing into anything else. A few transfer across into inspection of in-service plant but find it in much wider and more complex field, and difficult to gain credibility. There is often a route into being an inspection co-ordinator, but for this you need to like sitting in an office.

Salary levels

The LOWEST SALARY levels/hourly rate are for jobs where the source inspector is resident in one or two nearby locations (pipe manufacturing mill, boiler fabrication shop etc.). The technical scope is limited and repetitive but you can sleep in your own fluffy bed every night. Rates improve slightly for travelling inspectors who attend multiple works within daily travelling distance.

To achieve higher rates, it is almost essential to take on inspection assignments involving overseas travel to difficult locations and developing countries. Trips can be long and tiring, working entirely on your own in an unfamiliar culture.

Up to 75% of source inspectors are self-employed, in one way or another. This increases your overall income level, with only a marginal reduction in job security. Another way to increase your hourly rate is to specialise in a particular type of equipment in which clients recognise require specialist knowledge and experience. Examples are subsea/wellhead equipment, gas turbines, aerospace, boilers and some types of advanced refinery equipment.

Quality Management and other related bananas

DON’T CONFUSE Source Inspection with Quality Management. It’s a different thing. The parallel universe that is Quality Management cannot, it seems, decide whether it is governed by evolution or revolution. Its principles have evolved over the past 40 years or so with standards like ISO 9000 hanging on through time, changing their format, content and even their titles. All this to please the additional countries, institutions and committees that wish to be associated with them, or not, as the case may be. In the fevered search for yet more things to comply with, standards of similar format have come along offering compliance with the environmental, information security, personnel and even ethical requirements set out within their hallowed pages.

From time to time the relative peace of this evolution gets disturbed by some revolutionary new idea that comes along; the dull management equivalent, you could suppose, of the new kid on the block. Total Quality Management (TQM), Just in Time (JIT), Six Sigma (6σ), X-stream leadership (XSL no doubt), and the Quality Management by Deciding Nothing Method (QMBDN). Actually, I made that last one up, but you get the idea. These come along, flower for a while, then become so successful that they are quietly replaced by something else. Slowly, the status quo returns, with a few more recognised acronyms to add to the excitement.

DON’T WORRY… All of this fluttering away in the background does little to affect the less fluffy world of the source inspector. The mainstream API SIFE/SIRE certificates give most of their attention to the role of the inspector in technical issues such as materials, welds, corrosion, pressure and performance testing and similar, so all is well.

Interested in knowing details of competence required for API Source Inspector Exams? Try our API SIFE EXAM QUIZ QUESTIONS.

For typical job interview questions for source inspector positions, see Interviews for SI roles

Can we help you further?

We offer a TRIAL TECHNICAL INTERVIEW

If you want to check your knowledge for a specific job role in the integrity industry then try our trial technical interview. Its purpose is to test you on the technical aspects of the job you are thinking of applying for. There’s no time limit on it but expect it to last at least 20 minutes. After the discussion we’ll give you honest feedback on how you did. Just let us know the type of position you are going for; we’ll do the rest and respond with at time slot for you to call us.

There’s no charge, but we will expect you to call us at the allocated time and be ready to answer technical questions.

Remember your trial interview is on a purely technical subjects. We are not interested in you personality traits, do-gooding activities or any wonderful extra-curricular interests you may have.