INTEGRITY JOB ROLES

LESSONS LEARNED

Because not all career changes turn out as intended

Lessons learned

Unfortunately, not all career moves turn out to be a good idea. The asset integrity industry is a broad one, with 50-60 different job roles linked to the inspection/integrity field alone. With this breadth comes opportunity, plenty of related technical disciplines, and a selection of different hierarchy ladders to climb. A side effect of all of this is of course the risk of getting it wrong. A higher salary or hourly rate feels good at first but the effects can soon wear off if the new job is not as interesting or satisfying as you thought. Here are some real-life case studies we have seen. We should learn from them all.

Case study 1: It’s just more of the same

A NDT technician with 8 years’ experience of hands-on NDT of pressure equipment decided that the technical nature of the job was just too repetitive. Hourly payment rates increased marginally year-on-year but there was no clear route to career progression in sight, apart from the route into ‘operations management’. Additional qualifications in more advanced NDT techniques seemed to offer a solution, hopefully replacing simple ultrasonic testing (UT) with advanced phased array and long-range UT techniques. More complex NDT techniques, goes the argument, command higher hourly rates.

To start with, it worked OK. On the back of a couple of specialised qualifications a transfer was achieved to a full-time technician job using these new techniques, at a 30% higher hourly rate, because fewer technicians are qualified to it.

And the problem?

Over time (a fairly short time) the new daily routine because equally as repetitive as the old one. The increase in hourly rate was dependent on the technician have all the expensive equipment provided by their employer, so eliminating the possibility of crossing over to a self-employed position. Technology advances quickly, so buying specialised equipment is rarely a good long-term prospect. And that’s where it ended up – a different type of testing but, in terms of day-to-day activities, really just more of the same.

This is always a danger when staying in the same type of job.

Case study 2: The sweet Chalice of management?

You don’t have to look far to find a well technically-qualified person, doing a technical job well who professes that their ambition is to progress into so-called ‘technical ‘management’. In some organisations, it becomes a sugar-coated mantra-virus; hang around it long enough, and you too will catch it.

For those of you so affected, read on (take a deep breath first).

The technical world and its technical jobs are sharp-edged. Issues that are black and white are described as black and white in words spoken by people who are sharp-edged, so you can see where they start and finish. They say what they mean and mean what they say as they all work towards a technical answer that is there to be found. When they find it they hold it aloft, beaming from ear to ear, showing it to their friends.

The management world and its management jobs are about maintaining an uneasy and unsettling truce between characters who persist in seeing the same things in different ways whilst pretending otherwise. To help you, you have magnifying glasses and telescopes (all foggy) some smoke, and a fine set of double-sided mirrors. There are no sharp edges in the world around you – just curves and spirals. In the air are invisible spirits, layers of tissue-thin game-players imbued with a sense of aimless direction. The diamond-cut unbreakable rules of organisational cybernetics hold all this, and you, in its vice-like grip.

It’s a totally different job – that’s all I’m saying. Think carefully before you take one.

Case study 3: Welcome to…. Technological Armageddon

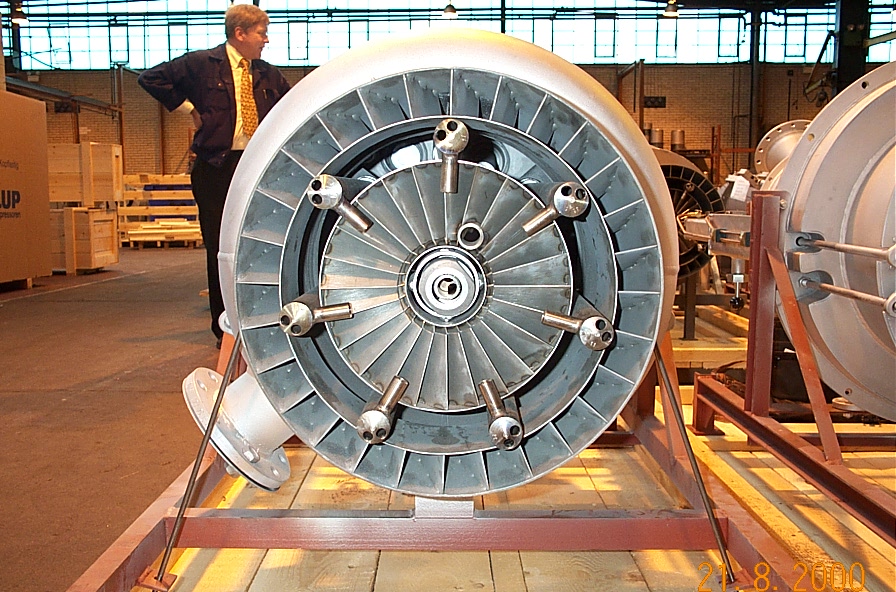

A new construction (source) inspector acquired 15 years of experience in monitoring the construction of simple types of pressure vessel. As the years progressed he felt increasingly confident to move into vessels of greater complexity, power boilers, ASME VIII Division II, multi-compartment and design by analysis (DBA) vessels.

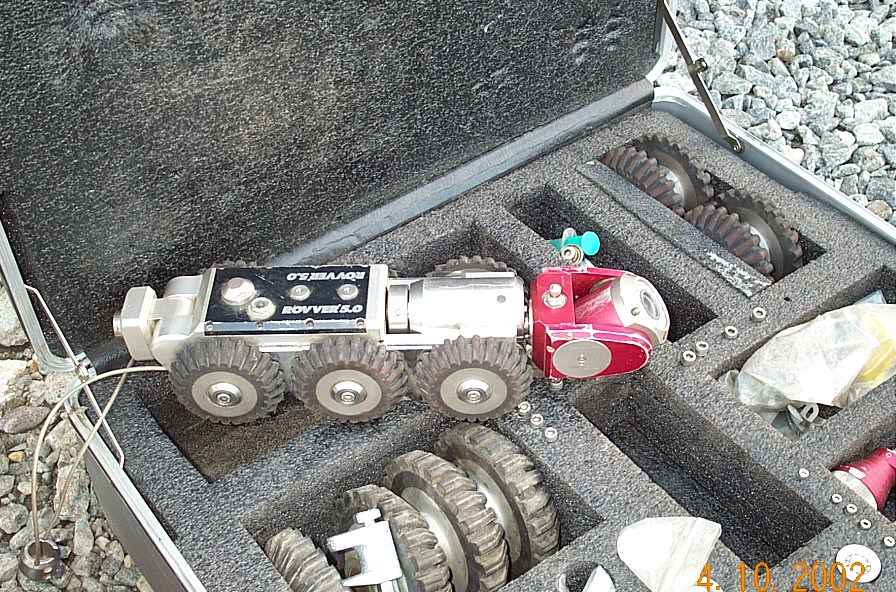

An increase in hourly rate was not as easy to achieve – clients did not seem keen to increase hourly inspection rates just for inspecting different types of vessels. A move into rotating equipment inspection seemed a logical progression, hourly rates were significantly higher and from the outside, the job didn’t appear to be that different. Here is this candidate’s honest appraisal as to how the first 6 months went in his new role as rotating equipment inspection for a large ‘turnkey’ engineering contractor.

‘In the first few weeks, they sent me to do contract inspections on parts of centrifugal pumps, which wasn’t too difficult. Verifying materials for the forged rotor parts and cast casings was much the same as for pressure equipment, once I had become familiar with the various different materials’

‘Witnessing my first pump performance test was awkward – the manufacturer had a test procedure to follow but expected me to know lots of technical background about pump performance testing that wasn’t written in there. I managed to check the gauge readings OK, but then the performance curves appeared as a vast computer printout, annotated with measurement tolerances, conversion factors and guarantee points that I was expected to agree to. The manufacturer didn’t seem interested in teaching me what was going on, apart from quoting a long list of other hydraulic standards I’d never heard of.’

‘As the year progressed the job changed to witnessing guarantee performance tests during plant commissioning. On one site in Africa there were extractor fans, turbo compressors and gas turbines all to be tested against the ASME PTC (Power Test Code) specifications. No-one had told me about these. They turned out to be scientific-looking documents written by single-subject specialists and full of graphs of performance data in multiple different units.’

‘I tried to follow the heated discussions between the contractor and purchaser, both of whom who seemed to think they were being short-changed in some way. One problem was that the contractor’s site was at an elevation of 2000 metres above sea level, whereas all the guarantee clauses had been written for plant installed at sea-level, where the air was denser. The gas turbine fuel quality was also different to that in the purchasing specification. Discussions about this went on for half a day, and I’m still not sure where they ended up. In in one single commissioning meeting I heard the terms adiabatic expansion, isentropic coefficient, non-sinusoidal vibration, isochronous governor hunting and adjusted free air delivery, all mentioned within half-an-hour.

I felt I just didn’t have the formal technical background to follow all this. It wasn’t anything like inspecting pressure vessels’

That’s how it went.

In the end, the technical step was just too large for this experienced inspector. Each day he felt he was surrounded by experts and his lack of knowledge shone through. Before long, manufacturers and test personnel didn’t seem very interested in asking his advice or for his interpretation of code documents, as they had done in the previous comfortable little world of pressure vessel inspection. Fortunately, it was not too difficult to take a sideways step back to pressure vessel inspection – the best route to take under the circumstances.

There are many variations on this theme of taking a step into a technical world you don’t understand. Mechanical inspectors can find it difficult to adapt to electrical, civil or rotating inspections, and vice-versa. Always watch out for the technical-knowledge trap. You can learn almost any type of technical knowledge if you try hard enough, but not everyone wants to.

Are career moves in the integrity industry always difficult?

Not necessarily; as long as you consider carefully what about what the nature and responsibilities of some of the job roles actually are before you apply for them. It pays to be cautious.

If you are an employer then watch out for job applicants who seem to apply for every position available, just to try to achieve a salary increase. Be wary of those who say they are looking for extra responsibility but really just want extra money. You have to be permanently on your guard against suspiciously multi-certificated applicants also; see our article; Beware of TICKET-COLLECTORS.

If you are an employee then watch out for jobs to be avoided.You really wouldn’t want to be applying for the one described in; Non-job of the week ,would you?

We offer a TRIAL TECHNICAL INTERVIEW

If you want to check your knowledge for a specific job role in the integrity industry then try our trial technical interview. Its purpose is to test you on the technical aspects of the job you are thinking of applying for. There’s no time limit on it but expect it to last at least 20 minutes. After the discussion we’ll give you honest feedback on how you did. Just let us know the type of position you are going for; we’ll do the rest and respond with at time slot for you to call us.

There’s no charge, but we will expect you to call us at the allocated time and be ready to answer technical questions.

Remember your trial interview is on a purely technical subjects. We are not interested in you personality traits, do-gooding activities or any wonderful extra-curricular interests you may have.