INTERVIEWS FOR INTEGRITY EVALUATION ROLES

Here are some tips and sample technical interview questions relating to jobs that have ‘Integrity Evaluation’ (or something similar) in their title. Before you read this article, first have a read through our short introductory articles Technical interviews in the world of asset integrity and Integrity job technical interviews; some facts to help put them in context.

What jobs are we talking about?

Job roles advertised under the banner of ‘Integrity Engineer’ vary widely in their scope of what you might actually do all day. Some of the various titles you will see are:

- Plant integrity engineer

- Asset integrity engineer

- Integrity assessor/co-ordinator

- Fitness for purpose assessor

- Code compliance engineer

The fact is that many of the job titles shown above may actually involve precious little technical integrity assessment, as such. Titles involving the words asset integrity and evaluation, alone or in combination, are becoming increasingly common, presumably because people think they sound good. You therefore need to dig a little under the surface of these job titles to expose what it is that the employer actually wants, as opposed to the implications of some impressive-sounding job title designed to bring in lots of enquiries from (hopefully) well-qualified candidates.

To avoid getting misled by a job advert for this type of role, have a look at our linked article on the Integrity Jobs page; The Integrity Engineer job; What’s this all about?

Most ‘Integrity Engineers’ come from one of two distinct career routes; In-service Inspectors or Engineering Graduates. These routes differ in the amount of practical experience and formal academic qualifications that candidates bring to the job. Not surprisingly, opinions about which is the better vary, depending on whom you ask.

Integrity Evaluation job interview questions; what to expect

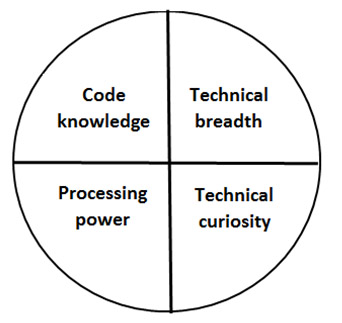

In our Integrity job technical interviews; some facts article, questions used in technical interviews were considered to be made up of categories or ‘quadrants’, as shown below;

As for in-service inspectors, the Integrity Evaluation role requires knowledge of all of these four quadrants, so you can expect questions to be wide-ranging and variable, depending on the knowledge of the interviewer. Overall you can expect interview questions to be more technically involved than those for a pure inspection position

Question 1. Defect evaluation criteria

Question.Where would you get guidance on defect acceptance criteria when assessing a corroded item of pressure equipment?

There’s all manner of answers to this question. Most commonly they come from post construction codes (PCCs) such as API 510/570/653.If an item fails these criteria then the next step is a FFP document such as API 579.The final stage involves finite element analysis.

The most common mistake is to confuse PCCs with new construction codes such as EN13445 or ASME VIII. Another is to start talking about Regulations such as PSSR, COMAH or PED, or material standards, or regress to relating the inspection procedures of your previous employer. None of these are PCCs and are the wrong answer.

One of your objectives as an interview candidate should be to find out the real level of technical analysis you will be required to do. PCC assessments can be done in a few minutes but detailed FFP assessments are almost a discipline in themselves and may involve you becoming a backroom resource staring at computerised analysis software and finite element analysis all day. Some people like this.

Question 2. Technical breadth

These questions are designed to weed out candidates whose don’t have sufficient formal technical knowledge to make decisions about the safety of degraded plant items. Here’s a typical one

Question.What theoretical evaluation methods could you use for a high temperature 1%Cr pressure equipment component which has been operating at 540 degC at 100 barG for 300,000 hours?

This is a good one for finding out whether someone understands a bit of metallurgy and damage mechanisms

Here are the tricks in it:

An operating temperature of 540 degC for 300,000 hrs is unreasonably high for a 1%Cr alloy. You’d be expected to spot this anomaly.

The question is not about NDT. It’s trying to lure you into the trap of describing PT or MT, or replication tests, when it’s the evaluation method that’s

- Life-fraction rules for fatigue

- Creep stage assessment

- Larsen Miller parameter

In practice, 1%Cr would probably have long since failed under these conditions; so you’d need to talk you way round this scenario.

You have to be careful not to take the wrong track when answering a question like this one. It’s all too easy to be seen as an NDE or visual inspection inspector and little else. To stand a chance of success you need to be able to show an appreciation of DMs, evaluation techniques and the codes and published documents that relate to them. API 510/570/571,577 and 579 are good places to start. For overland pipelines it’s API 571, API 1169, DNV RP-101, ASME B31G and their referenced documents.

Test yourself on Integrity Evaluation knowledge with our TRIAL TECHNICAL INTERVIEW

We offer a TRIAL TECHNICAL INTERVIEW

If you want to check your knowledge for a specific job role in the integrity industry then try our trial technical interview. Its purpose is to test you on the technical aspects of the job you are thinking of applying for. There’s no time limit on it but expect it to last at least 20 minutes. After the discussion we’ll give you honest feedback on how you did. Just let us know the type of position you are going for; we’ll do the rest and respond with at time slot for you to call us.

There’s no charge, but we will expect you to call us at the allocated time and be ready to answer technical questions.

Remember your trial interview is on a purely technical subjects. We are not interested in you personality traits, do-gooding activities or any wonderful extra-curricular interests you may have.