INTERVIEWS FOR IN-SERVICE INSPECTOR ROLES

Here are some tips and sample technical interview questions relating to In-service inspector jobs in the integrity industry. The Matthews Integrity Hub:HEAD OFFICE website contains a series of these, relevant to different jobs in the industry. Before you read the individual sets, first have a read through our short introductory articles Technical interviews in the world of asset integrity and Integrity job technical interviews; some facts to help put them in context.

What jobs are we talking about?

This is perhaps the widest generic category of inspection jobs in the integrity industry. It ranges from inspection of refineries, power stations and all other types of process plants. Numerically most of the jobs are land-based but the category also includes oil & gas offshore installations. The work is often linked to statutory regulations (such as PSSR and COMAH) but has a strong technical element to it also.

Don’t confuse in-service inspection jobs with pure NDE technician activities. NDE plays a big part in in-service inspection but is not the same as the wider inspection role. In-service inspectors rarely perform the NDE themselves, being more involved in monitoring, reporting and assessing the results.

See our linked article: NDE and asset integrity: The Difference

Let’s look at a few facts about in-service inspection jobs

They are much more technically complicated than the small-plant ‘engineer surveyor ‘role

- Inspectors need specific knowledge about how the equipment works, and the damage mechanisms likely to affect it. Inspection of refinery equipment tends to be the most complex of all

- Certifications are split into multiple API qualifications

- Inspectors need an appreciation of design codes, post-construction codes and defect acceptance criteria to do their job properly

- A lot of inspection work is done during plant shutdowns or ‘turnarounds’ (TARs)

Most in-service inspectors come from NDE, plant operations or mechanical technician backgrounds. Some have higher technical qualifications (because some employers require them) but the job remains one which required significant practical experience to do it well.

The result of this is that technical interviews for In-service inspection positions can be very variable, whether you are an employer or a candidate. For refinery jobs in particular they can be technically difficult, with candidates expected to show they know what refinery equipment does and how it works.

In-service inspector job interview questions; what to expect

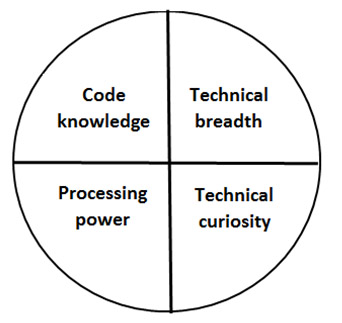

In our Integrity job technical interviews; some facts article, questions used in technical interviews were considered to be made up of categories or ‘quadrants’, as shown below;

Unlike some roles, the In-service inspector role requires knowledge of all of these four quadrants, so you can expect questions to be wide-ranging and variable, depending on the knowledge of the interviewer.

Let’s look at a good technical interview questions from some of the quadrants They are not intended to be easy questions (or everyone would get them correct), or unfeasibly difficult ones, but they are meant to be searching questions. Here they are, with commentary for both candidates and employers;

Question 1. Post-construction codes

Question. Explain which post-construction codes have an influence on the in-service inspection of pressure equipment, and how they differ from their corresponding construction codes?

This is a question full of menace. Many inspectors, and even their employers may have never heard of post-construction codes (PCCs).A lot of older-style ‘inspection surveyor’ companies instruct inspectors to follow their own in-house procedures rather than published PCCs so if your experience lies with one of these then you will find this question difficult to answer.

The most common mistake is to confuse PCCs with new construction codes such as EN13445 or ASME VIII. Another is to start talking about Regulations such as PSSR, COMAH or PED, or material standards, or regress to relating the inspection procedures of your previous employer. None of these are PCCs and are the wrong answer.

Here’s the bones of a decent answer to the question (note that the question is in two parts, to check if you were listening)

First part of the question: Explain which post-construction codes have an influence on the in-service inspection of pressure equipment?

API 510 is a PCC relating to unfired vessels, as is NBIC-23. A technical support document for vessels is API 572.Process pipework and components are covered by API 570 and RP574 and above ground storage tanks by API 653 and RP575.ASME PCC-2 is relevant to inspecting repairs on all types of pressure equipment. There are many others for specialized pieces of equipment

Second part of the question: How do PCCs differ from their corresponding construction codes?

API PCCS are based on the construction principles of their corresponding construction code i.e. ASME VIII-I for vessels, ASME B31.3 for process pipework and API 650 for storage tanks. PCCs allow additional leeway and margins over the prescriptive requirements of construction codes in areas such as defect acceptance levels, PWHT procedures, minimum allowable wall thickness and hydraulic testing. PCCs also include guidance on damage mechanisms and in-service repairs whereas new construction codes do not.

Question 2. Technical breadth

These questions are designed to weed out inspectors whose have narrow experience and a blinkered approach. If you are one of those then you need to do your preparation before the interview. Here’s a typical one

Question.What’s the difference between inspecting an air receiver and a large circular above-ground storage tank. ?

This is a good one for finding out whether someone understands what in-service inspectors do and the many types of equipment they might get involved with. Here are two wrong answers and why:

Answer: Air receivers are more dangerous as they are more likely to fail. Sounds good but not true

Answer: There’s not much difference; the principles are much the same. Incorrect; storage tanks have lots of varied and unpredictable specific damage mechanisms (DMs) owing to the fluids they contain. Air receivers have a handful of simple DMs. Air receivers have large in-build design margins; storage tanks have much smaller ones. Storage tank inspection tends to be a specialist discipline; whereas air receiver inspection is precisely the opposite.

Better answers

Ways to construct a better answer would be:

Answer: Air receivers (in the UK) are statutory items covered by The PSSRs so specific written schemes of examination (WSE) inspection activities and reporting are required. Atmospheric storage tanks do not fall within PSSR jurisdiction, although they may be covered by COMAH regulations

OR

Answer: Storage tanks have a large number of varied in-service DMs covered by API 653,575,571 and EEMUA 159.Air receivers have a few simple DMs; the main ones being:

- Internal/external wall thinning or pitting (mainly a leak-before-break DM)

- Fatigue of unsecured pipework

- Safety valve problems

You have to be careful not to take the wrong track when answering a question like this one. It’s all too easy to be seen as a small-plant air-receiver inspector and little else. You need to be able to show an appreciation of the in-service inspection of as wide a range as possible of other plant types and the DMs and published documents that relate to them

Type 3: Processing power-type interview questions

Here are some examples of question topics designed to check out your mental processing power. Note that none are about NDE; that’s a different subject.

- How would you calculate the hoop stress on a pressure vessel that has 50% wall thinning?

- Here’s a copy of ASME B31.3. Have a read through it for 5 minutes then come back and explain to me what is in it

- Explain what Risk Based Inspection (RBI) is and what are its strengths and weaknesses?

You have to use your processing power to think about each of these carefully to compose an answer. That’s what the questions are testing.

We offer a TRIAL TECHNICAL INTERVIEW

If you want to check your knowledge for a specific job role in the integrity industry then try our trial technical interview. Its purpose is to test you on the technical aspects of the job you are thinking of applying for. There’s no time limit on it but expect it to last at least 20 minutes. After the discussion we’ll give you honest feedback on how you did. Just let us know the type of position you are going for; we’ll do the rest and respond with at time slot for you to call us.

There’s no charge, but we will expect you to call us at the allocated time and be ready to answer technical questions.

Remember your trial interview is on a purely technical subjects. We are not interested in you personality traits, do-gooding activities or any wonderful extra-curricular interests you may have.