FFP studies: The Dangers

You don’t have to be around long in the plant integrity industry before you get to hear about fitness-for-purpose (FFP) studies. They are particularly common in the upstream oil & gas and the downstream (refinery) industry, and installations that operate old plant or under arduous corrosion conditions.

FFP studies: What are they?

A FFP study is a technical evaluation of a corroded or damaged item to see if it can be declared still safe and suitable for service. They may be called ‘fitness for service’ (FFS) assessments, ‘authoritative technical reviews’ or something similar but they are all much the same thing. Note the common points about them:

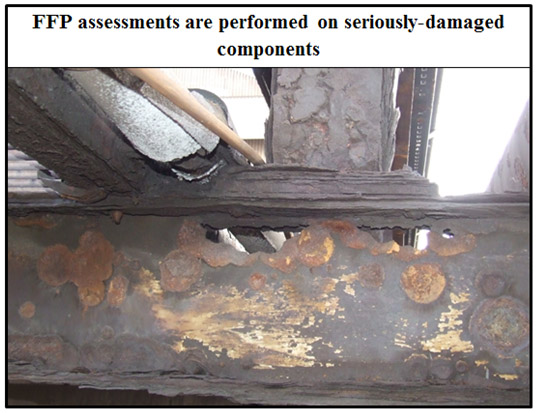

- The component in question is normally significantly corroded or damaged in some way (otherwise why you would there be the need for a FFP assessment)

- It’s a purely technical assessment concerned with the probability of failure rather than the consequences of failure (that’s a different thing)

- Most FFP studies follow the guidance of some published guidelines, recommended practice or other technical publication of some sort. Technical people love to write this sort of stuff.

- Plant operators think that commissioning a FFP study from an external person or organisation may help their defence if a failure does occur, because they might be able to blame it on the assessor. See our linked article: Accident? It wasn’t MY fault.

Hidden among this mix of sensible-enough features lies the general objective that most plant operators would like the result of a FFP study to say that their plant is safe to use, rather than there being a catastrophically dangerous accident just waiting to happen. Fair enough you could argue. That’s what FFP studies are.

How are they done?

This is a bit like asking where do people go for their holidays? There are hundreds of different types of FFP assessment methodologies, employing well-established technical publications such as:

- API RP 579 Fitness for service :1000+ maths-packed pages relating to refinery and related equipment

- ASME B31G: Manual for determining the remaining strength of corroded pipelines

- BS 7910: Guide to methods for assessing the acceptability of flaws in metallic structures

All of these are written by multiple contributors, involving large committees and their voting procedures. Given this array of technical wisdom (and the list above is only a start) you might conclude that there are many, many ways to do a FFP study, and lots of options as to how to do it.

So where’s the danger?

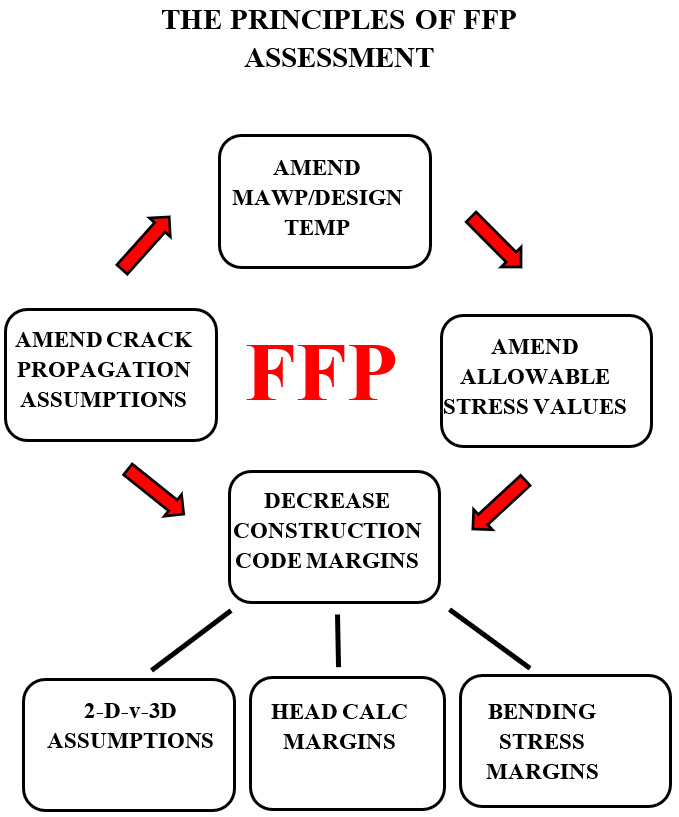

One feature of FFP studies is that they are designed to be carried out on items that are corroded/damaged outside the limits of acceptability of their design/construction code (ASME, EN or whatever).The FFP concept is that the code contains large margins of safety on just about everything and a FFP study just allows some of these to be used up a bit .This gives an extra leeway on what a safe defect size, minimum wall thickness or operating pressure may be. So where’s the danger?

The danger lies in the assessment method, or more precisely the multiplicity of them that are available to use for any specific damage case. Given all the methods available, with their attendant mass of technical assumptions it is not that difficult to get any specific result you want. A corroded pressure vessel shown to be safe under one set of assumptions and evaluation methodology can look in imminent danger of failure under a different set. There is not, and can never be, a single answer to any FFP question, given the variety complexity of the methods and the assumptions that lie behind them.

The danger lies in the assessment method, or more precisely the multiplicity of them that are available to use for any specific damage case. Given all the methods available, with their attendant mass of technical assumptions it is not that difficult to get any specific result you want. A corroded pressure vessel shown to be safe under one set of assumptions and evaluation methodology can look in imminent danger of failure under a different set. There is not, and can never be, a single answer to any FFP question, given the variety complexity of the methods and the assumptions that lie behind them.

For pressure equipment, design/construction codes, whilst not always a legal requirement, are well accepted by most HSE enforcing authorities as valid benchmarks of good practice and acceptable risk. This is reinforced in countries/jurisdictions where these have legally-binding ‘code’ status. FFP documents, in contrast, come under the category of ‘guidance’ or ‘recommended practice’ status. They are therefore much less likely to be accepted as benchmarks, not least because each can contain multiple or conflicting benchmarks to add to the confusion.

Let’s review the danger

So, there are two dangers of using FFP studies

- If you do a FFP assessment on a damaged piece of equipment using the ‘wrong’ assessment method, your conclusion as to whether it is safe or not MAY be WRONG

- If you do operate a piece of equipment which a FFP study suggests is safe and it DOES FAIL, then your FFP study WAS wrong, because the item has failed. In these circumstances, expect to have some very awkward questions to answer as to why you continued to operate a large ‘risk gap’ under conditions of foreseeable danger. Far from working in your favour, the existence of the FFP study may be claimed as evidence that you foresaw the plant was unsafe and tried to get away with it, rather than any mitigating feature of what has happened.

It’s not written in any of the FFP documents as far as we can see but it might be a good idea, before accepting the results of any FFP study of your plant to do a few Google searches and look at the results for Refinery explosions, Gas Explosions, Chemical releases, US Chemical Safety Board case studies and things like that. Maybe you can assume that one of the accidents shown happened as the result of a corroded plant item for which you recently signed off the FFP report.

Let’s get rid of some misconceptions

FFP studies can be very useful in the right circumstances but there are a few misconceptions around about them, particularly relevant after a serious accident has happened and a prosecution case is in place.

- There is only one answer to a FFP study: NO, there are many different and conflicting ones.

- If there is a failure injuring people, my FFP study will protect me. You can answer this one yourself. If it was that good, and considered everything, then how come the item failed?

- After a failure my FFP assessor will give evidence in my defence. Possibly,if you can find them. Alternatively, they may claim you didn’t supply them with all the correct information so it was your entire fault.

- In a court case, my FFP assessor will be considered a technical God. Sorry, NO. Every single expert witness from the opposing side will explain why they would have done the assessment a totally different way, and that’s why your equipment failed and caused the accident.

FFP evaluation jobs

Integrity evaluation and FFP studies roles are just about the top of the technical tree in the asset integrity world. These jobs don’t always carry high positions in the management hierarchy but are more interesting in a technical sense than spending your day doing personnel planning spreadsheets, budget predictions and things like that.To get a feel for the technical aspects of integrity evaluation/FFP studies have a look at typical Interview questions for integrity evaluation roles,and its linked technical quizzes.

If you have any technical questions on FFP studies, give us a call and we’ll try to help

We offer a TRIAL TECHNICAL INTERVIEW

If you want to check your knowledge for a specific job role in the integrity industry then try our trial technical interview. Its purpose is to test you on the technical aspects of the job you are thinking of applying for. There’s no time limit on it but expect it to last at least 20 minutes. After the discussion we’ll give you honest feedback on how you did. Just let us know the type of position you are going for; we’ll do the rest and respond with at time slot for you to call us.

There’s no charge, but we will expect you to call us at the allocated time and be ready to answer technical questions.

Remember your trial interview is on a purely technical subjects. We are not interested in you personality traits, do-gooding activities or any wonderful extra-curricular interests you may have.