HSE enforcement: do you feel lucky (Sir)?

About enforcement

In the UK the main body for enforcing H&S law compliance is the Health and Safety Executive (HSE) which is a national body. On a local basis a role may also be taken by local authorities (LAs) for smaller plant in government buildings etc.

Enforcement authorities have a hard job. Like all government bodies they always feel they are short of money and don’t have enough staff, thereby making their job of enforcing H&S law a difficult one. They love their bureaucracy too, leaving even fewer of their already-restricted numbers to actually go out and do inspections and generally enforce compliance with the law. You can do the maths on this yourself and see that, if visited in strict rotation, each plant operating company in the UK would only receive a HSE visit every (large) number of years, given the number of inspectors available. The result of this is that most HSE inspections tend to be reactive (to accident events) rather than pro-active. There’s nothing inherently wrong with this, apart from perhaps increasing the impression that the main role of the HSE is one of enforcement rather than assistance.

One organisation, many voices

Like in any organisation, enforcing authority inspectors are a wide and varied bunch. Given the statutory nature of their task however, wild and untamed enthusiasm is rarely appreciated in a government-regulated body so some constraint on their activities would seem to be a good idea. What might such a constraining procedure look like? It would need to;

- Guide what a HSE inspector should do, when enforcing H&S law

- Justify what an inspector has already done (big organisations being heavily into self-justification)

- Be sufficiently flexible to allow multiple legitimate outcomes or justify a single outcome, both at the same time. Tough job that one.

It’s already here

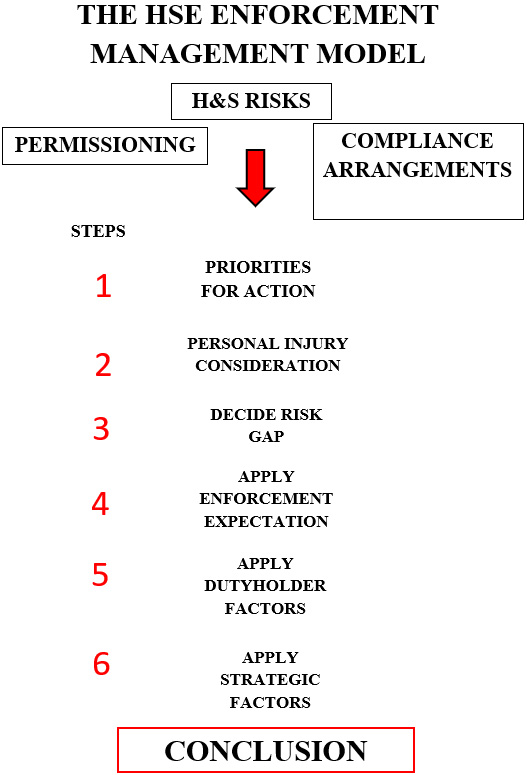

It’s been around since 2002, in the form of the HSE Enforcement Management model (or EMM) as it is known. You can download it from the HSE website on www.hse.gov.uk/enforce/emm.pdf .The core of the document is the step-by-step flowchart as shown below, taking you through the enforcement steps in a logical manner. Remember that this document is written as a model designed for HSE inspectors to follow, not a guide to compliance for duty holders, but it makes interesting reading just the same.

Note the following key points ((you’ll need to read the document first to appreciate them properly):

- It differentiates between causing a risk and just administrative non-compliance

- It explains the concept of the ‘risk gap’ as a measure of non-compliance ( a well-established concept)

- It introduces the concept of benchmark risk (an interesting one)

- It explains the role of codes and standards (in a fashion)

Following this lot towards the end of the document are two features called duty-holder factors and strategic factors. You can think of these (rightly or wrongly) as factors which help the enforcing authority decide their chance of winning in a prosecution court-case involving a jury. Duty-holder factors are actions that have the potential of making a duty-holder (under prosecution) look particularly bad or careless. Examples are the duty-holder skimping on H&S provisions to save money, ignoring previous inspections, deliberately hiding the truth and things like that. Strategic factors are those affecting wider issues such as the protection of the public interest, vulnerable people and the general message passed to industry and the public. Both dutyholder and strategic factors have the advantage that they are non-technical and capable of being understood by judges and juries, who decide on the outcome.

Understanding the EMM

The EMM is well-written and has stood the test of time. As a duty-holder it is well worth reading it before you get involved in any dealings with HSE. Remember that it is written to apply to many types of HSE prosecutions, not specifically plant integrity so you have to apply its content to the subject in hand to see fully how it applies to you.

Two issues are particularly worth looking at in relation to the mechanical integrity of plant; the foreseeability of risk and risk benchmarks. These have specific interpretation that can have a direct effect on the enforcement, particularly after an accident has happened. Read a discussion of these in our linked article: Integrity risk: foreseeability and benchmarks

Matthews Integrity Hub: HEAD OFFICE is OPEN EVERY DAY….0730 – 2200 Monday – Sunday…That’s correct, all week, every week, including holidays

If we happen to miss your call, leave a message and we will call you back just as soon as we pick it up. Sorry, there’s no automated messages, call queueing, voice recognition tools or canned music. Try it and see.

If we happen to miss your call, leave a message and we will call you back just as soon as we pick it up. Sorry, there’s no automated messages, call queueing, voice recognition tools or canned music. Try it and see.

CONTACT US

Tel: 07746 771592 help@matthewsintegrity.co.uk