CODE SNIPPET

The API SIFE STUDY GUIDE

The API SIFE PROGRAMME: WHAT IS IT?

The API SIFE (Source Inspector Fixed Equipment) is a personnel certificate programme for ‘source’ inspectors (SIs) who inspect fixed equipment (pressure equipment and fabricated structures) during manufacture, as opposed to during in-service use. As with all API certification programmes there is a published body of knowledge (BoK) and code ‘effectivity list’ listing all the codes that form the subject matter of the programme.

The SIFE study guide book

To complement the codes listed in the BoK, API publishes a 50-page document entitled Guide for Source Inspection and Quality Surveillance of Fixed Equipment (see Figure 1). This can be downloaded from the API website. In addition to acting as part of the exam BoK, it provides a useful and realistic background to the role of source inspection. In time, this may be issued as a more formal API recommended practice (RP) document. Note a few important points about this SIFE guide.

- It provides a useful elaboration on the code ‘effectivity list’ that makes up the BoK.

- It identifies specific technical points within referenced codes that are deemed important to SIs.

- Large numbers of SIFE exam questions are sourced from this document, in preference to the detailed content of the referenced codes. Its style and content make it suitable for API-style closed-book questions.

The best way to approach this document is to look at a few of the most important sections, to gain an understanding of how it is put together.

An important point: don’t confuse the SI and AI

Remember that for ASME VIII vessels built in the USA and other countries accepting ASME jurisdiction, the ASME BPVC requires the presence of an authorised inspector (AI) during design and construction. Do not confuse this with the role of the API source inspector (SI). Just think of the SI as a more general, less ASME-specific incarnation of the AI, not restricted to the code requirements of the ASME BPVC, and with a wider, less code-prescribed role and duties.

SIFE guide section 4: Definitions abbreviation, acronyms

All API documents contain a definitions section (4), to clarify the meaning of terms and acronyms used in the document. Most are common sense and match the generally used meaning of the words, but a few have their own meaning. Key acronyms from section 4 are the following:

- EPC: This is the engineering design construction company responsible for building a large plant. On completion, they hand it over to the owner/user.

- S/V: This represents the supplier/vendor. Typically they construct smaller plant assemblies (skid-mounted equipment for example) for supply to the EPC.

- M/F: The manufacturer/fabricator(s) who actually manufacture the component parts (vessels, pipework, valves and so on). There will be hundreds of these in a large EPC construction project.

Next consider the other parties with involvement in the source inspection activity;

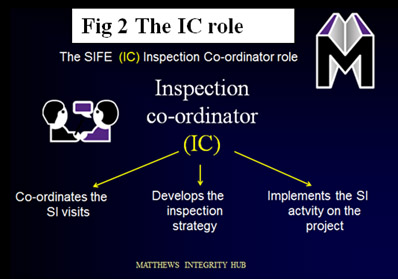

- The inspection co-ordinator: works for the source inspection company, co-ordinating the inspection visits of SIs. The role also provides a link back to the function of administering inspection reports, NCRs and engineers’ approvals of concessions to specification compliance.

- SI: The source inspector themselves (you). This title is not universal – in many industries and countries it is more commonly known as the shop inspector or works inspector.

SIFE guide sections 5, 6, 7

These are set out as

- section 5: Training and certification

- section 6: Source inspection management programme

- section 7: Project specific source inspection planning activities.

Section 5 Training and certification breaks down the level of training and experience for SIs into four levels; entry level, basic level, stand-alone level and master level. The idea is consistent within itself, but is, as yet, not used in industry practice.

Section 6 Source inspection management programme makes good sense but offers less information than its title suggests. It is simply a management system, the purpose of which is to provide the SI with all the information they require to work on projects. The system is generic so can be used for all SI projects.

Section 7 Project specific source inspection planning activities is a more specific version of section 6. The principle is given below.

- Source inspection should be directed towards the materials and equipment that need it most.

You can think of this as a risk-based approach to source inspection and, as with all risk-based assessments, it needs input from several parties and people to ensure it is done well. In real-world situations, not all projects get this right, leading to

- SI activity being wasted in multiple inspections on fairly dependable (low-risk) manufacturing processes and components

- High-risk, potentially more awkward, situations only being subjected to light surveillance or none at all, with inspection input limited to review of paperwork.

This is a classic scenario, explaining how serious non-compliances can slip through the SI activity that is supposed to catch them

SIFE guide section 8: Source inspection programme

You can think of section 8 as a collection of explanations as to how the source inspection process is done, rather than containing technical details, as such. The list below shows the breakdown.

8.1: Inspector conduct and safety

8.2: Review of project documents

8.3: Performing the source inspection

8.4: Scheduled planning events (i.e. meetings)

8.5: Report writing

8.6: Non-conformances/deviations

8.7: Project continuous improvement

8.8: Source inspection continuous improvement

Section 9.2: Materials of construction

This is the most useful part of section 9 of The SIFE Study Guide as it has strong practical application. Rogue materials are an increasing problem, and it is the SI’s job to find them.. API 578: Material verification programmes is in the SIFE BoK. It covers positive material identification (PMI) tests and techniques; note, however, that it is concerned more with preventing mix-ups between carbon steels and alloy steels than the issue of counterfeit materials from unreliable sources.

The other sections of the SIFE study guide

The remaining sections (10–14) of the SIFE study guide are made up of brief summaries of relevant bits of the following codes.

- Metal forms, properties and metallurgy (from API 577)

- Weldability and hardenability of metals (also from API 577 but more detailed)

- Basic information on pressure vessels (from API 572)

- Basic information on piping and valves (from ASME B31.3, B16.5 and API 598)

SIFE exam preparation

If you wish to progress to sitting the API SIFE exam (see our SIFE exam article) .You can expect perhaps 35–45% of the exam questions to be lifted directly from this guide ; some using verbatim wording and others based on general principles, in association with some specific technical wording. The SIFE study guide is therefore a useful introduction to the world of source inspection.

API also run a similar Source Inspection Rotating Equipment (SIRE) certification programme covering equipment such as pumps, turbines, compressors, gearboxes and their sub-components such as bearings and seals. SIRE is more specialised than SIRE but many of the same principles apply. Contact us through our helpline if you need more information on this programme.

For further details on what the Source Inspector does during construction, see our Source Inspector Role article

Matthews Integrity Hub: HEAD OFFICE is OPEN EVERY DAY….0730 – 2200 Monday – Sunday…That’s correct, all week, every week, including holidays

If we happen to miss your call, leave a message and we will call you back just as soon as we pick it up. Sorry, there’s no automated messages, call queueing, voice recognition tools or canned music. Try it and see.

If we happen to miss your call, leave a message and we will call you back just as soon as we pick it up. Sorry, there’s no automated messages, call queueing, voice recognition tools or canned music. Try it and see.

CONTACT US

Tel: 07746 771592 help@matthewsintegrity.co.uk